A robust product genealogy unlocks complete traceability of raw materials in the manufacturing process which results in better compliance, higher quality standards, and faster root-cause analysis. Implementing genealogy was not easy for most of the manufacturers due to challenges like technological complexities, siloed data, cost, time, training needs etc. However, the scenario has changed after artificial intelligence became highly mature. The implementation and usage of genealogy has become easier and extracting information has become faster and more convenient with the modern AI advancements.

AI’s role in building Genealogy

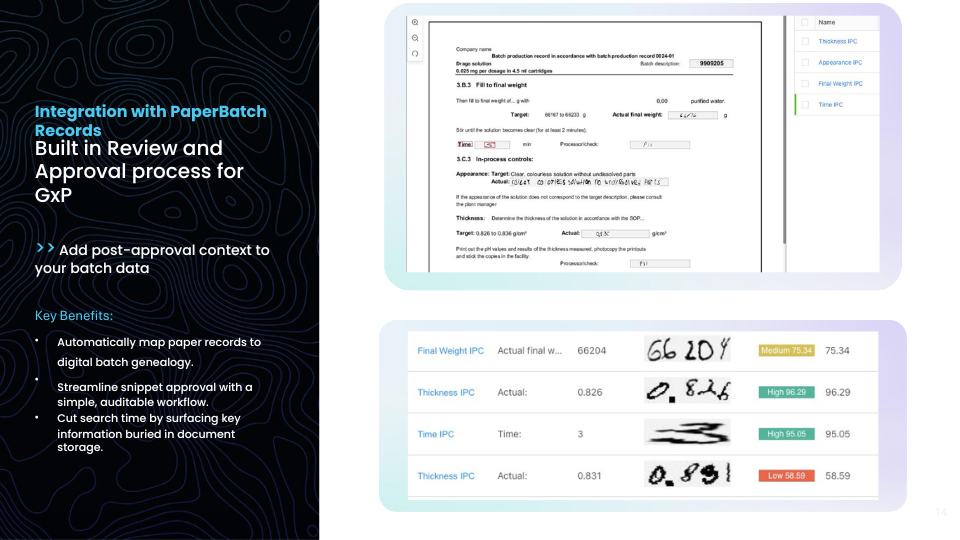

Traditionally, building a complete genealogy required manual extraction of data from paper batch records, spreadsheets, and siloed systems. It was a slow and error-prone process that could take weeks or even months. Moreover, the problem didn’t end at paper, even digital systems often rely on relational databases, which aren’t well-suited for tracking the hierarchical nature of product genealogy. We need better data models (like graph or document-based approaches) that reflect the true shape of the data. AI addresses this challenge by automating both the digitization and structuring of manufacturing data at scale. For instance, we use pharma-specific OCR engine with machine learning algorithms to extract and contextualize critical information from handwritten and printed records. This eliminates the need for manual data entry, and reduces efforts for paper batch record digitization by up to 90%. Once the data is digitized, the AI engine uses the knowledge graph architecture to automatically create the genealogy by mapping materials, equipment, process steps, and outcomes without manual intervention. Years of batch history can be processed and structured in just hours, enabling QA and manufacturing teams to access complete traceability faster than ever before. Additionally, AI can collect the data from different CMOs and CDMOs, and understand it correctly without the need for standardization to create genealogy.

AI’s role in Understanding Genealogy

Genealogy turns complex manufacturing data into intuitive, visual formats. AI-powered Manufacturing Intelligence platforms like Mareana can present a clear, interactive map of how raw materials, intermediates, and final products are connected. Users can explore these maps through forward and backward tracing, making it simple to follow the full path of a batch from incoming materials to finished goods. This visual representation helps users of all technical backgrounds make sense of the data without needing deep system expertise. Behind the scenes, AI connects and contextualizes data from multiple sources, such as batch records, LIMS, sensor data, and even external manufacturing partners. Using algorithms and machine learning, AI automatically builds the relationships needed to generate complete and accurate genealogy views. This reduces the need for manual input or subject matter expert intervention and ensures that the data shown is both current and relevant. The result is a more efficient, user-friendly way to validate, analyze, and understand batch histories for faster investigations, better decision-making, and stronger compliance.

AI’s role in Uncovering the Data in Genealogy

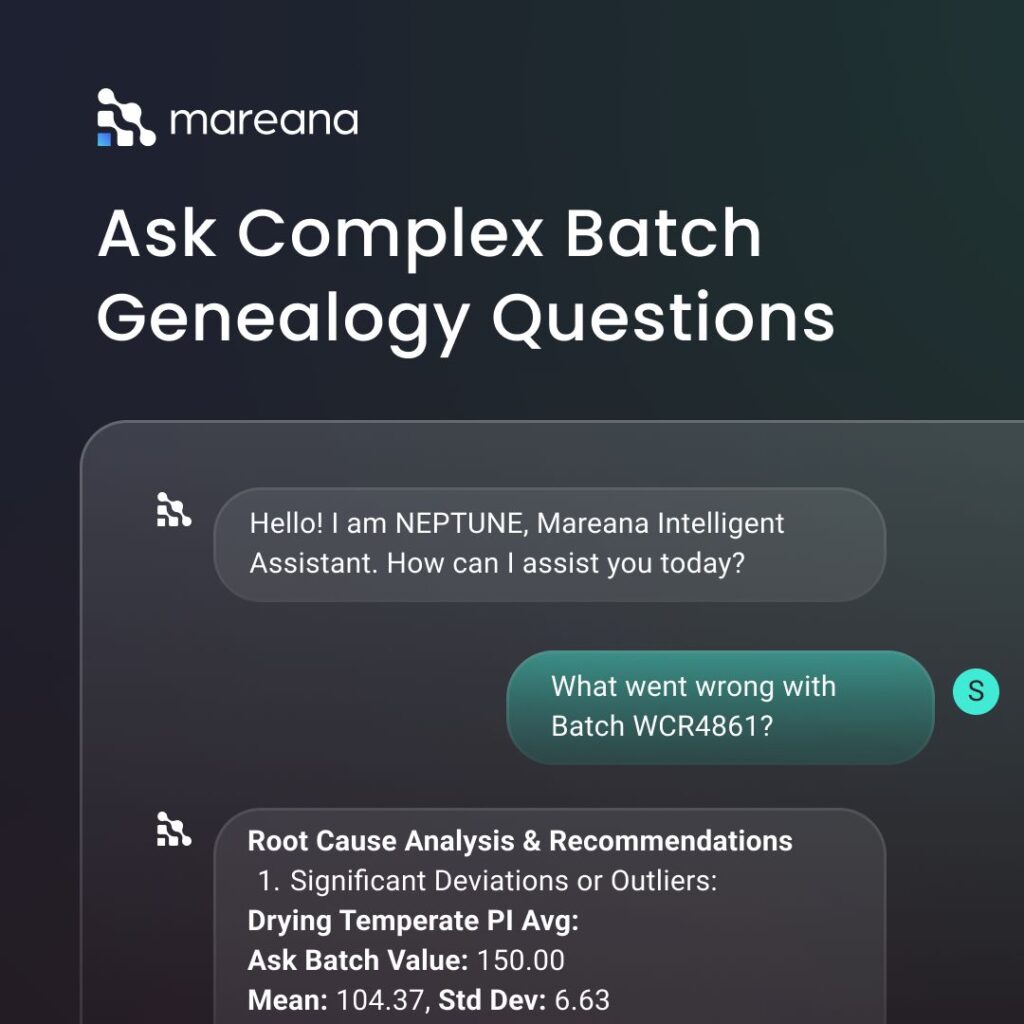

AI is also playing a key role in making genealogy data more accessible by enabling users to interact with it through purpose-built chatbots. Rather than navigating through complex data structures or searching manually within genealogy maps, users can now simply ask questions in natural language. For example, a user might ask, “How many batches were produced using material XYZ?” or “What were the top 10 most used materials in the ABC plant last year?” or “Give me a list of deviations that occurred in the past six months”, etc. The chatbot retrieves accurate answers instantly, without requiring users to manually explore or filter data within the genealogy system. In case of Mareana’s Manufacturing Intelligence platform, our AI assistant – “Neptune” is designed specifically to understand the structure, context, and language of manufacturing genealogy. Trained on domain-specific data, it allows users to uncover precise information about materials, batches, deviations, and trends with minimal effort. Once the relevant data is retrieved, users can perform additional operations such as trend analysis, mathematical calculations, or root cause investigations directly on that dataset. This interaction model reduces the dependency on technical expertise, speeds up decision-making, and makes the power of genealogy usable for a broader range of users across QA, manufacturing, and operations.

Whats’s Next?

Implementing genealogy can be extremely useful for ensuring end-to-end traceability, accelerating investigations, and maintaining compliance. It helps reduce manual effort, minimize errors, and provides faster access to critical batch and material data. If you are looking to implement genealogy in your pharmaceutical manufacturing process, connect with us and our experts will help with all your queries related to implementation, costing, data security, integration with existing systems, or any other aspect specific to your operations.

Frequently Asked Questions (FAQs)

1. What is product genealogy in pharmaceutical manufacturing?

Product genealogy is a comprehensive record of how raw materials, intermediates, and finished goods are connected throughout the manufacturing process. It enables complete traceability, helping pharmaceutical manufacturers ensure compliance, maintain quality, and conduct faster root-cause investigations.

2. Why is implementing product genealogy traditionally difficult?

Building genealogy has historically been challenging due to data silos, manual processes, and complex systems. Manufacturers often rely on paper batch records or spreadsheets, which make tracking materials and processes slow, error-prone, and time-consuming.

3. How does AI simplify the creation of Product Genealogy?

Artificial Intelligence automates data extraction and structuring from various systems, including paper records, LIMS, and sensor data. Using pharma-specific OCR and knowledge graph architectures, AI can process years of manufacturing history within hours, creating a fully connected genealogy map without manual intervention.

4. How does AI help users understand and visualize genealogy data?

AI-powered manufacturing intelligence platforms, like Mareana, provide interactive visual maps that display material and process connections. Through forward and backward tracing, users can easily explore batch paths, identify root causes, and validate data—all without deep technical expertise.

5. What advantages do AI chatbots offer in navigating genealogy systems?

AI-driven chatbots such as Neptune allow users to query genealogy data using natural language. Instead of manually searching through datasets, users can ask questions like “Which materials were used in batch 101?” and receive instant, accurate responses. This accessibility speeds up investigations and decision-making.

6. How does AI ensure better data accuracy and compliance in genealogy?

By digitizing and contextualizing manufacturing data, AI eliminates manual errors and maintains ALCOA+ compliance standards (Attributable, Legible, Contemporaneous, Original, Accurate). It ensures that all traceability records are accurate, current, and easily auditable for regulatory inspections.

7. Can AI integrate genealogy data from multiple CMOs and CDMOs?

Yes. AI systems can collect, interpret, and harmonize data from multiple contract manufacturers and partners, even if formats differ. This eliminates the need for rigid standardization and enables a unified, enterprise-wide genealogy view across complex supply chains.

8. How can companies start implementing AI-powered genealogy systems?

Manufacturers can begin by assessing their current data landscape, identifying key systems to integrate, and selecting an AI platform specialized in life sciences, like Mareana’s Manufacturing Intelligence. Partnering with experts ensures smooth deployment, data security, and optimized performance tailored to operational needs.

9. What are the main benefits of AI-driven product genealogy?

AI-enabled genealogy provides:

• Complete end-to-end traceability

• Faster root cause analysis

• Improved compliance and audit readiness

• Reduced manual workload and human error

• Enhanced collaboration across QA, manufacturing, and operations

Learn more

Learn more