Artificial intelligence (AI) is transforming the quality control process in drug manufacturing in several ways.

- Improve inspection accuracy and speed up the process. AI-powered systems can analyze vast amounts of data and images collected during the manufacturing process and identify any deviations or anomalies that may affect product quality.

- Prevent equipment breakdowns that may impact drug quality. AI algorithms can be used to analyze data from sensors and other sources to predict when manufacturing equipment may need maintenance or repair.

- Improve product quality and reduce costs. AI can analyze data from the manufacturing process to identify opportunities to optimize production processes, such as reducing waste or improving yields.

- Prevent quality issues from occurring. AI can be used to monitor manufacturing processes in real time, allowing for immediate corrective action if any deviations or anomalies are detected.

- Identify potential quality issues before they become a problem. AI algorithms can be used to analyze large volumes of quality control data to identify patterns and trends that may be difficult to detect using traditional methods.

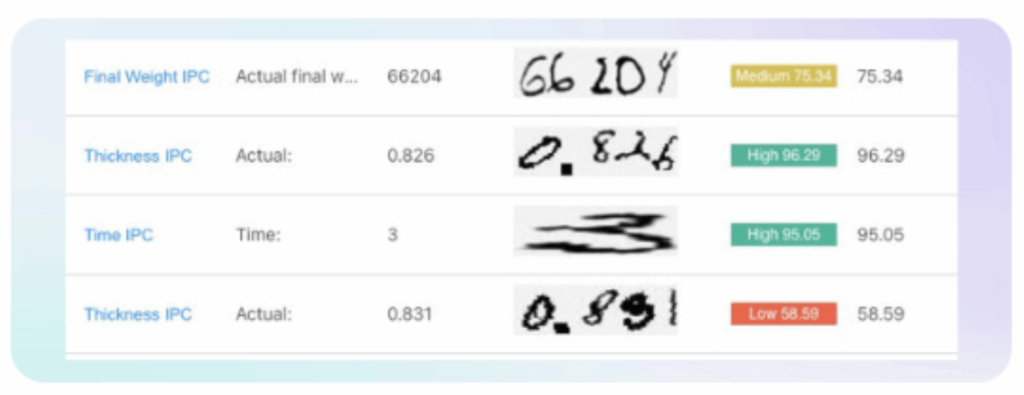

The image below is an example of Mareana’s AI-powered manufacturing intelligence platform being used by QA in batch reviews. The tool scans the paper batch records and digitizes hand written text intelligently. It also provides a confidence score to the digitized data, telling the reviewer how confident it is with the character recognition. This intelligence enables review-by-exceptions, where the batch reviewer spends his time only on the values where AI could not understand confidently.

Challenges of AI Adoption in Drug Manufacturing

While AI has the potential to revolutionize drug manufacturing, there are still several hurdles to its widespread adoption. Here are some of the biggest challenges:

- Data quality and availability: AI systems rely heavily on high-quality data, and the quality of the insights generated by AI algorithms is only as good as the quality of the data they are trained on. However, in drug manufacturing, data is often incomplete or inconsistent and may be scattered across various sources. Therefore, it can be challenging to ensure that there is enough high-quality data available for AI to work effectively.

- Regulatory challenges: Regulatory agencies have strict requirements for drug manufacturing processes to ensure patient safety. These regulations can be complex and difficult to interpret, making AI technologies challenging to integrate into the manufacturing process without violating any rules.

- Integration with existing systems: Implementing AI in drug manufacturing requires integration with existing systems, such as quality control, process control, and manufacturing execution systems. However, legacy systems may not be compatible with AI solutions, making integration challenging and time-consuming.

- Cost: Implementing AI in drug manufacturing can require a significant investment in technology and personnel. This investment may be difficult to justify for smaller companies or those with limited budgets.

- Data security and privacy: Drug manufacturing involves sensitive information, including patient data and intellectual property. Ensuring the security and privacy of this data is critical, and implementing AI technologies requires robust security measures to protect against cyber threats.

Vishal Prasad, Chief Product Officer at Mareana, further comments in Phorum Technology Conference, “Pharma is a high margin industry, so inaction is always an option. Secondly, it is a regulated industry, so the the threshold with which you have to prove that your digital product works is also very high.”

Quality Control in Drug Manufacturing: Manual vs. Digital Solutions

There are key areas where digital solutions have proven more reliable than humans when it comes to processes historically done manually. Here are a few scenarios:

- Decision-making: AI algorithms can be trained on a specific set of rules or criteria to make consistent decisions every time. Human decision-making can be influenced by a variety of factors, such as experience, mood, and workload, which can lead to inconsistencies in quality control decisions.

- Analytics: AI can use machine learning algorithms to analyze historical data to identify patterns and predict future outcomes. For example, AI can predict when a particular piece of manufacturing equipment is likely to fail or when a quality issue is likely to occur. Humans may not be able to detect these patterns or make these predictions accurately.

- Data: AI can also handle complex data sets that may be difficult for humans to interpret or analyze. For example, AI algorithms can look at complex molecular structures to identify potential quality issues in drug formulations. This ability requires a level of expertise and training that may not be readily available among human quality control professionals.

Overall, AI can exceed human capabilities in quality control by providing faster, more accurate, and more consistent decision-making based on vast amounts of complex data. Leveraging AI can ultimately lead to better product quality and patient safety.

Frequently Asked Questions (FAQs)

1. How is artificial intelligence transforming quality control in drug manufacturing?

AI is revolutionizing pharmaceutical quality control by automating data analysis and inspection processes. It quickly detects deviations or anomalies in production, allowing manufacturers to maintain consistent quality standards. AI also improves efficiency by reducing manual errors and enabling real-time decision-making during production.

2. What are the main benefits of using AI in pharmaceutical manufacturing?

The key benefits include improved accuracy, faster quality inspections, predictive maintenance, and reduced operational costs. AI helps optimize yields, minimize waste, and maintain consistent product quality — all while ensuring compliance with strict pharmaceutical regulations.

3. How does Mareana’s AI-powered platform enhance the batch review process?

Mareana’s AI-powered manufacturing intelligence platform brings review-by-exception capabilities to quality assurance. It scans and digitizes handwritten batch records, assigns confidence scores to recognized data, and flags only uncertain entries for human review. This intelligent automation allows QA professionals to focus on exceptions rather than manually checking every record, significantly reducing review time and improving overall accuracy.

4. What challenges do pharmaceutical companies face when adopting AI technologies?

Companies often face issues such as incomplete or inconsistent data, regulatory hurdles, system integration challenges, high initial investment, and data security concerns. Ensuring data quality and aligning AI tools with compliance frameworks are critical for successful adoption.

5. How does AI prevent equipment breakdowns in drug manufacturing?

AI-driven predictive maintenance systems analyze data from sensors and operational logs to detect early signs of equipment wear or malfunction. By forecasting when maintenance is needed, these systems prevent unplanned downtime and maintain product consistency throughout the manufacturing cycle.

6. How does AI compare to manual quality control methods?

AI systems can process vast and complex datasets much faster and more accurately than humans. Unlike manual reviews, AI ensures consistent decision-making and reduces human bias. This leads to fewer production errors, faster turnaround times, and improved overall reliability in quality control.

7. What role does data play in AI-driven drug manufacturing?

High-quality, well-structured data is essential for effective AI model training and reliable insights. Inconsistent or scattered data can compromise prediction accuracy. Establishing strong data management and integration practices is key to achieving AI-driven quality improvements.

8. Is AI adoption cost-effective for smaller pharmaceutical companies?

Although AI implementation requires upfront investment, it delivers substantial long-term returns by reducing waste, improving yields, and lowering maintenance costs. Scalable cloud-based AI platforms make it increasingly accessible for small and mid-sized pharmaceutical firms.

9. How does AI ensure data security and privacy in drug production?

AI technologies in pharma use strict security protocols, including encryption, access control, and compliance with data privacy regulations. These measures protect sensitive information such as patient data, proprietary formulations, and operational records from unauthorized access or cyber threats.

10. What is the future of AI in pharmaceutical quality control?

The future lies in fully digitized, AI-integrated manufacturing systems that offer real-time monitoring, predictive insights, and self-optimizing processes. Companies like Mareana are leading this transformation, enabling smarter, faster, and more transparent quality assurance across the drug manufacturing lifecycle.

Learn more

Learn more