Digital twin technology is gaining traction in the pharmaceutical industry, boosting drug development efficiency and paving the way for advancements like personalized medicine.

A digital twin is essentially a virtual model of a physical system or process that allows for real-time simulation, analysis, and monitoring. This technology is a game-changer for pharmaceutical companies, enabling precise outcome predictions, streamlining processes, and slashing both time and costs in drug development and manufacturing.

However, adopting digital twins in pharma comes with hurdles, notably integrating high-quality data and managing it across platforms—a critical foundation for creating accurate and effective digital twins.

Mareana CPV steps in as a solution, guaranteeing the precision and reliability of digital twins in pharmaceutical manufacturing.

Achieve Digital Twin Excellence with Mareana

Mareana offers a pathway to leverage digital twins more effectively, driving significant value in terms of operational efficiency, product quality, and speed to market. Here’s a breakdown of how Mareana streamlines data integration, elevating the digital twin application:

Enhancing Precision Through Genealogy

At its heart, Mareana features a genealogy or detailed mapping of the steps and data involved in pharmaceutical manufacturing, making it easier to follow and analyze the entire process.

By working through historical data, Mareana algorithms create highly contextualized data models upon integration with relevant source systems. This access to vast volumes of data enables data scientists to mirror physical processes with unmatched fidelity, thereby elevating the precision of digital twins.

Unifying Insights with Comprehensive Data Integration

What sets Mareana apart is its unparalleled capability to aggregate and contextualize data from a myriad of sources, including ERP, MES, LIMS, Historians, PLC/DCS, PAT, paper batch records, and Certificates of Analysis (CoA). This robust data integration not only enriches digital twin models but also facilitates flexible data connections with Contract Manufacturing Organizations (CMOs).

Accelerating Outcomes with Real-Time Data

The proficiency of Mareana in handling real-time data feeds into digital twins ensures immediate accuracy for simulations and predictions, a critical feature for applications demanding swift decision-making based on the latest data. Here are two pivotal examples:

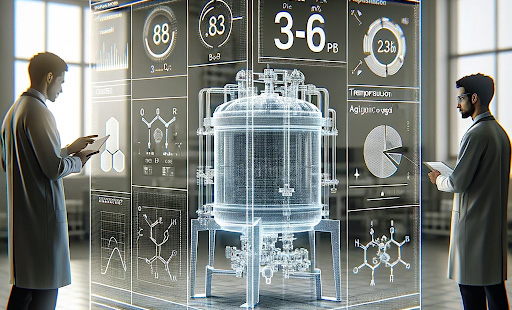

Yield Optimization in Bioreactors

Mareana streamlines crafting digital twins for bioreactors, effortlessly merging real-time data—temperature, dissolved oxygen, pH, agitation speed—with media and feed’s detailed material characteristics. This integration simplifies complexity, enabling the digital twin to predict bioreactor yields with unprecedented accuracy and elevating yield optimization to new heights.

Refining RTRT Models

Using Mareana in crafting RTRT models showcases its utility in fine-tuning API concentration and ensuring content uniformity. Leveraging NIR/Raman PAT data alongside DoE calibration insights, Mareana enables the crafting of models for real-time release predictions, aligning closely with the need for precision and regulatory compliance in pharmaceutical manufacturing.

Bridging Theory and Practice Using Physics-Based Models

Beyond data integration, Mareana’s Data Science Studio offers the tools for developing physics-based models, supported by an array of Python libraries. This opens new avenues for creating digital twins that are not just data-driven but also grounded in physical realities.

Encouraging Cross-Functional Collaboration

Mareana fosters unparalleled cross-functional collaboration by bringing together data scientists, subject matter experts, and various teams on a unified interface. This integration ensures seamless access to the digital twin and advanced modeling tools, enhancing communication and decision-making, thereby streamlining processes and promoting a more cohesive operational environment.

Elevate Manufacturing Excellence with Mareana-Enhanced Digital Twins

Mareana serves as the technological backbone that enriches the concept of digital twins in process manufacturing. Mareana helps improve process understanding, optimization, and control by providing the data, tools, and capabilities necessary to create highly accurate, dynamic, and predictive models of physical systems. It offers a pathway to leveraging these virtual models more effectively, driving significant value in terms of operational efficiency, product quality, and speed to market.

Discover how Mareana can empower your pharma operations and elevate your digital twins to unprecedented levels of efficiency and effectiveness. Request a free demo.

Learn more

Learn more