Navigating lifecycle-long regulations can be extremely challenging, laborious, time-consuming, and complex.

The Labyrinth of Drug Development Regulations

Navigating lifecycle-long regulations can be extremely challenging, laborious, time-consuming, and complex. The entire drug development cycle is lengthy and complex. It normally takes a decade or so and entails these five laborious steps according to the FDA:

- Discovery and development. Researchers assess new insights into a disease process to be able to design a product to stop or mitigate the effects of the disease. This step includes molecular testing, resulting in the discovery of new drugs through currently available treatments and new technologies. This also involves drug experiments for information gathering and the discovery of potential drug benefits, the best dosage and intake, side effects, drug compatibility, effectiveness, etc.

- Preclinical research. This includes in vitro and in vivo trials and the drugs go through laboratory and animal testing to answer basic safety questions. The use of best lab practices in accordance with medical product development regulation is a prerequisite here. Regulations involve study conduct, staff, facilities, protocols, and SOPs, etc.

- Clinical research. This now involves trials conducted on people to answer questions related to a product. In this phase, it is decided who qualifies as participants, their number, the duration, control group, administration, assessments, etc.

- FDA drug review. This is when the FDA conducts their review of the medical product when the pharmaceutical company submits a New Drug Application. It is up to the FDA whether to approve or reject it, and then the FDA advisory committee gives their feedback.

- FDA post-market drug safety monitoring. When the drug goes to market, the FDA needs to review reports of incidents, issues, and problems related to the drug, and then decide to add dosage cautions, usage information, and other safety measures.

Keeping an eye on this end-to-end process to ensure compliance throughout is nearly impossible for pharmaceutical companies who are mostly faced with too much information scattered across multiple sources and departments — some of which are even paralyzed by manual processes.

Data Is “Beyond Siloed”

Various systems are producing data. And in the pharmaceutical industry, the so-called “data tidal wave” phenomenon states that “90 percent of all data that exists has been created in the past two years.”

Using manual and non-standard processes to collect and integrate data can lead to inaccuracies, inefficiencies, and human errors. Pharmaceutical companies that use non-standard and manual batch record processes typically encounter several issues, including:

- Incorrect data entry

- Missing signatures

- Incomplete forms

These issues result in reduced regulatory compliance and lack of data traceability. Hence, companies need to spend more time on data wrangling, which is an important but not mission-critical step in achieving compliance.

Change Is Constant — And Dynamic

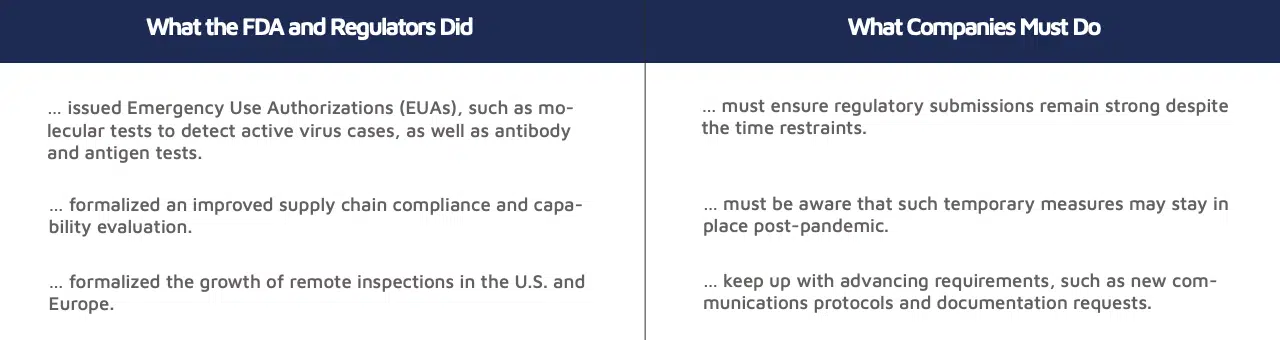

Regulations are always dynamically changing. Aside from changes in the drug development process, changes in regulations are also a challenge for pharmaceutical manufacturers.

For instance, during the height of the COVID-19 pandemic, regulatory bodies eased several compliance requirements to avoid supply shortages, enhance manufacturing capacity, and ensure self-sufficiency. And in the wake of the pandemic, for example, the FDA and other regulatory bodies proposed new changes in regulations to strengthen the healthcare sector’s response to crises.

Moreover, last February in the United States, the FDA brought forward four recommendations to Congress to avoid medical product shortages. These recommendations are as follows:

- Require longest expiration dates that are scientifically justified to alleviate shortages.

- Require periodic risk assessment to application holders to effectively assess and address vulnerabilities in the medical product manufacturing supply chain.

- Strengthen data-sharing requirements to better equip the FDA for the assessment of critical infrastructure and manufacturing quality and capacity.

These changes can benefit pharmaceutical manufacturing companies, but they also introduce new challenges and make navigating lifecycle-long regulations even more complicated and difficult.

Using traditional and manual capabilities alone may not be sufficient to manage compliance complexities. Pharmaceutical companies need an enabler that allows for the easy navigation of lifecycle-long regulation.

Uncomplicate Compliance with AI and Deep Learning

McKinsey, the global consulting firm, assesses that effective data strategies may produce up to $100 billion worth of cost benefits annually in the U.S. healthcare system alone. By leveraging solutions that use AI and Deep Learning, pharmaceutical companies not only remove the hurdles that complicate compliance, but also introduce real value to their processes and operations.

The greatest advantage of using AI and Deep Learning powered solutions is that — unlike other tools — they continuously learn and scale with IT and business requirements. AI is any software algorithm that has human-like features such as:

- Learning

- Planning

- Problem-solving

These three AI attributes can be constantly groomed — specifically for the type of industry where it will be used — and made more intelligent. Deep Learning is an AI technology that cab be used to swiftly and seamlessly process and analyze huge amounts of data — and the algorithm tends to learn over time and become more intelligent, thus producing better outcomes for repeated tasks. In the life science sector, that means AI and Deep Learning will constantly adapt to ever-changing regulations, allowing pharmaceutical companies to quickly respond to a dynamic regulatory landscape.

A Success Story

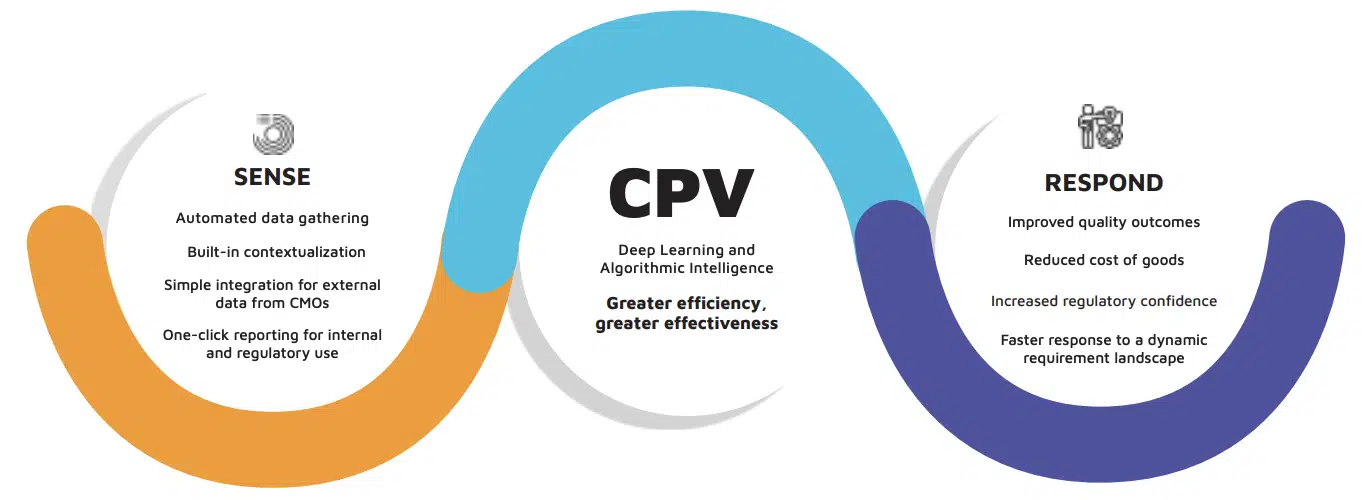

A global pharmaceutical company used Mareana’s Continued Process Verification (CPV) — an AI and Deep Learning powered solution — to standardize its processes across sites and simplify meeting their CPV requirements.

Prior to using the AI-powered solution, the company was having difficulty with its CPV reporting due to multiple systems producing data, which led to unnecessary complexity. The company also had to contend with process variability across sites, lacked a standard process to show data traceability, and was encumbered by manual data processing. Consequently, they spent more time on data gathering than problem analysis.

When they took advantage of Mareana’s CPV solution, they were able to automate and standardize processes across all sites. Even report generation became easier because Mareana’s CPV enabled one-click reporting for internal and regulatory usage. They were able to easily manage variations in systems and simplify integration for external data from CMOs using the solution’s built-in contextualization. As a result, the organization was able to navigate CPV easily and shift its focus from data and compliance issues to improving quality.

Comply More Intelligently with Mareana

Faster response to a complex and dynamic regulatory landscape requires faster “sensing” of changes in regulations.

Mareana’s Continued Process Verification (CPV) solution allows you to sense changes not only in regulations but also in your manufacturing and supply chain processes that can impact your organization’s compliance.

Mareana’s Continued Process Verification (CPV) uses smart algorithms and AI to enable an automated, standardized process. It allows you to shift your focus from data issues to product quality improvement and successfully meeting CPV requirements.

Providing you with advanced capabilities such as built-in contextualization and one-click reporting for internal and regulatory use, Mareana’s CPV allows you to meet regulatory requirements by:

- Automating data gathering using built-in connectors

- Digitization using AI models

- Managing variations through configurable alerts to control the quality

By using Mareana’s CPV, you will be able to maximize data assets for continuous improvement and innovation and increase regulatory confidence. Increased regulatory confidence takes away the focus from data gathering to process and quality improvement, enabling your organization to respond better to dynamic regulatory and process requirements.

Conclusion

Navigating lifecycle-long regulations like FDA’s Continued Process Verification (CPV) can be made less challenging if you have full visibility into data, processes, and people across your sites. It will be less complex if you can get automated alerts on any changes. It will be much simpler if you can automatically access, generate, and share regulatory reports with concerned stakeholders. Achieving and maintaining compliance is easy with AI and Deep Learning so that you can focus on process and quality improvement, accelerate time-to-value, and maintain a good brand reputation.

If you want to experience how AI- and Deep Learning-powered solutions like Mareana CPV simplify navigating lifecycle-long regulation, contact us to schedule a demo.

Learn more

Learn more